Spherical roller bearings feature two rows of symmetrical barrel rollers on a spherical outer ring track. As a result, shaft deflections and misalignments of the bearing seats are compensated.

A high load capacity and symmetrical tension distribution are achieved via the suitable fit between rollers and raceway.

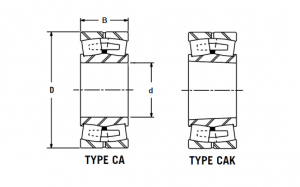

The bearings are available with cylindrical and tapered bore, and possess a lubricating groove and lubrication bores in the outer ring.

Standards

Spherical roller bearings, DIN 635, Part 2

Cages

Spherical roller bearings have a machined brass cage. Sheet metal cages are available at request.

Tapered bore

Spherical roller bearings are either made with a cylindrical or a tapered bore. Bearings with a tapered bore are usually mounted on the shaft by means of adapter or puller sleeves. In this case the reduction of the radial clearance must be taken into consideration. Spherical roller bearings of the series 240, 241, 248 and 249 normally have a taper ratio of 1:30 and the other series feature a taper ratio of 1:12.

Angle alignment

Spherical roller bearings can compensate for misalignment of up to 0.5°. If loads are low, angular misalignments of up to 2° are admissible.

Tolerances, bearing clearance

Spherical roller bearings of the basic design are manufactured with standard tolerances. Clearance groups are according to DIN 620, Part 4 and ISO 5753 (letter code C5).